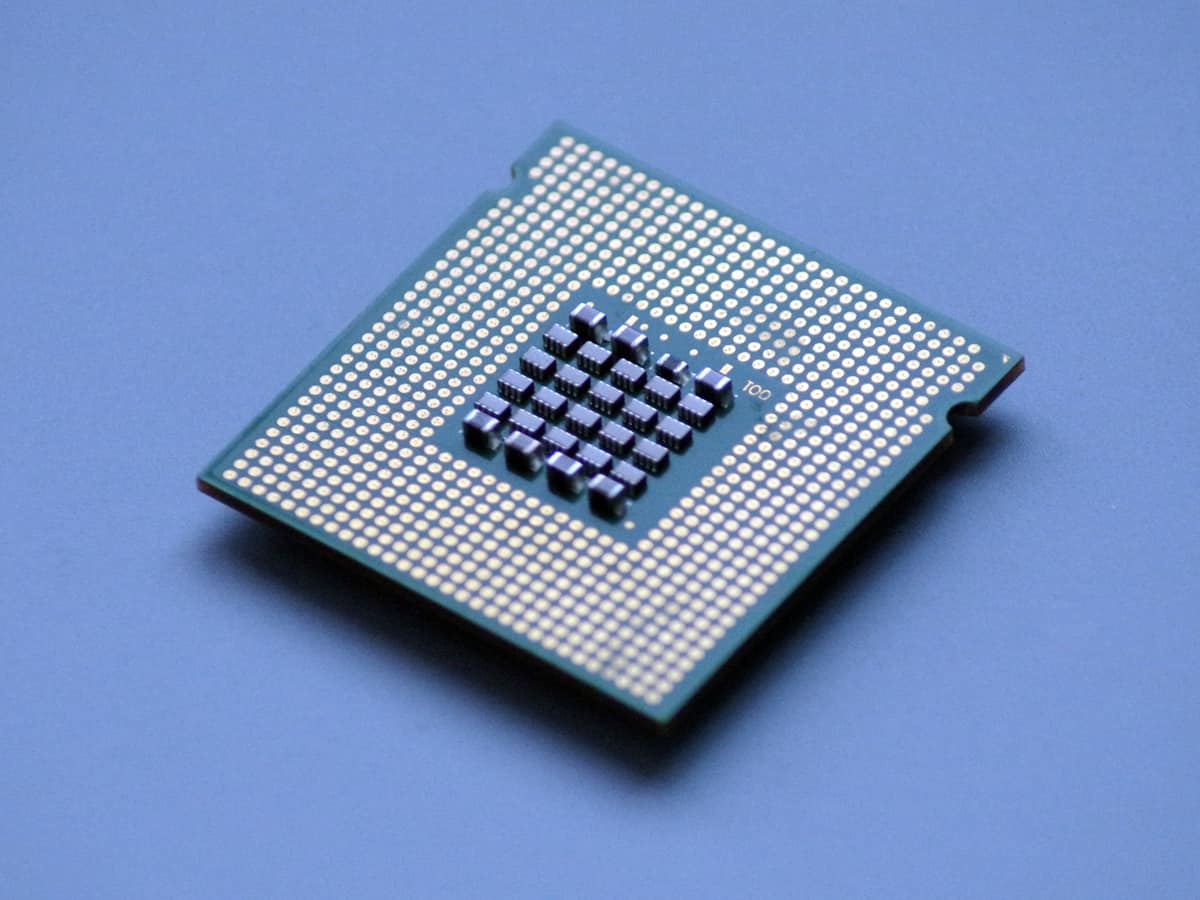

San Francisco: Chips for chipmaking machines are one of the things in short supply amid chip shortage constraints, say executives from Intel and Apple chipmaker TSMC.

According to 9To5Mac, buying new chipmaking machines was never a speedy process, given their complexity and delicacy, but lead times before the pandemic were measured in months.

While many commentators say they expect the chip shortage to ease by the end of this year, the WSJ reports chipmaking companies describing that as an overly optimistic view.

What began as a pandemic-era aberration of supercharged demand for laptops and other chip-hungry gadgets has spiraled into a structural problem for the industry.

Now many chip executives say the problem will persist into 2023 and 2024, or even longer.

Some chipmakers are prioritising clients who produce chipmaking machines.

Ganesh Moorthy, CEO of Microchip Technology Inc., a maker of microcontroller chips that process data in all kinds of electronic devices, including chip-making equipment, said his company now is treating chip-equipment suppliers as priority customers, not unlike the way it treated medical-device manufacturers at the onset of the Covid pandemic.

Intel and Apple chipmaker TSMC are among those calling for this approach to be more widely adopted.

A recent industry white paper argued the benefits of such a “multiplier effect”. A sophisticated testing tool requires 80 specialist chips that can be reprogrammed after they are produced, the analysis said, but then aids in making 320,000 of those same chips each year.