One more startup in the Space sector is on the rise from Hyderabad. TakeMe2Space has announced its arrival in the vast, expansive and tough space arena with its coating product that promises to help satellites and users.

The company has come up with a radiation shielding coating on top of Aluminium for satellites. It can cut costs, boost life of satellites and help satellite builders. It is made of tantalum metal, says Ronak Samantray, Chief Executive Officer (CEO) and one of the founders.

“Imagine a world where building satellites is as easy as putting together a Lego set. That’s the dream of TakeMe2Space. It has set out on the route to achieve with a revolutionary new technology that could make it a reality,” he says.

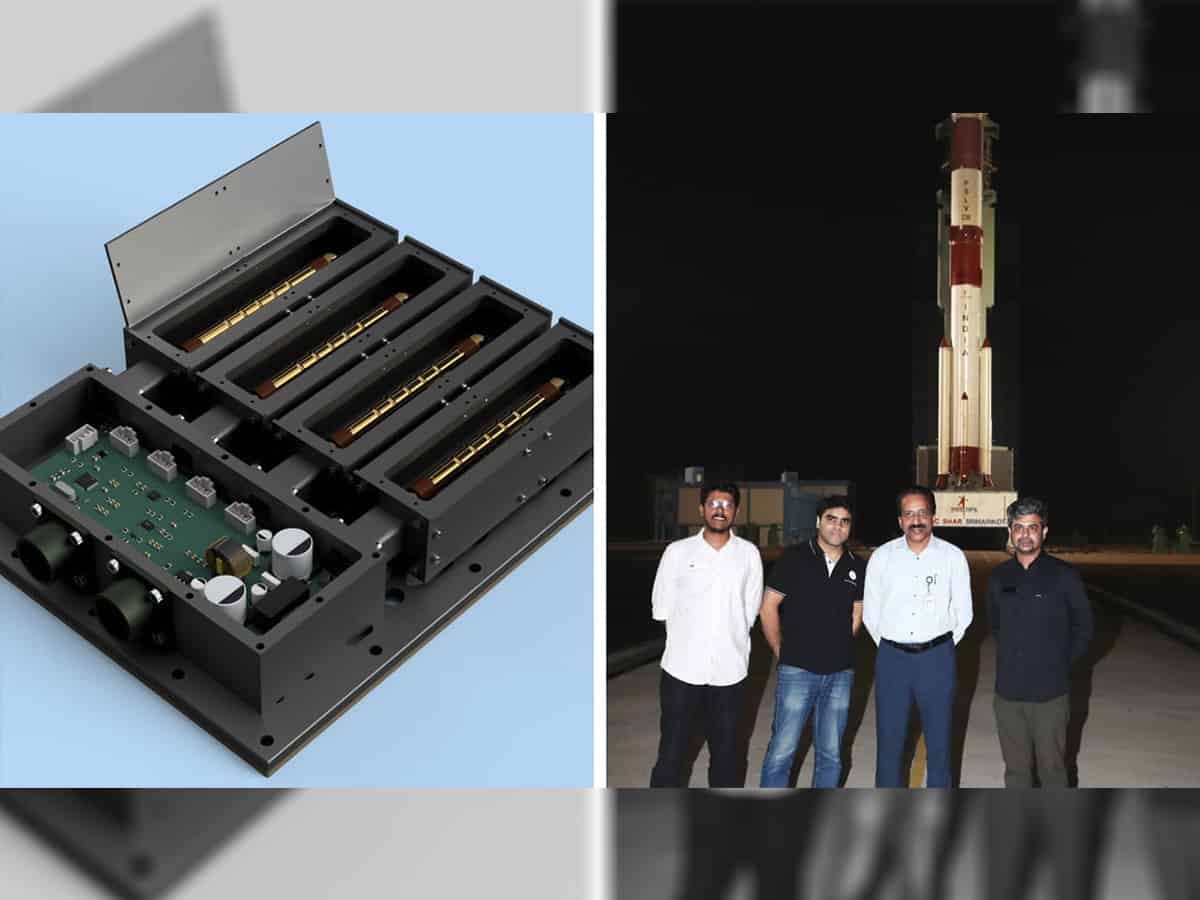

On January one, 2024 the prototype product called the Radiation Shielding Experimental Module (RSEM) was validated by the Indian Space Research Organisation (ISRO) on its POEM platform (PSLV Orbital Experimental Module), which allows in-orbit scientific experiments.

The PSLV C58 had placed the XPoSat ( X ray Polarimeter Satellite) and 10 other payloads into the low earth orbit (LEO) in a smooth launch from the Satish Dhawan spaceport in Sriharikota, helping the ISRO begin 2024 with a bang.

Also on board was a product developed by another Hyderabad-based startup Dhruva Space. Skyroot Aerospace is the other startup from the city which has been making big strides in the competitive spacetech sector.

The TakeMe2Space Story

The startup already has a fairy tale like run. Started in June 2023 by Ronak and 3 friends in his home near the Gandipet lake of Hyderabad, TakeMe2Space has got a prototype product for space business validated in 6 months.

In this quick fire beginning, it has benefitted from the collaboration with the T Works of the Telangana State Government in prototype building, the School of Engineering of the University of Hyderabad (UoH) in material science and the Apollo Hospitals Group in radiation studies.

The self-funded startup has a core team of four—Ronak, Sharat, Firoze and Nilav, all Engineers. “Our larger plan is to create Satellite based Orbital Infrastructure for all. For example, create satellite infrastructure in space and lease it to customers across the world. It will help many researchers and commercial operators to get their relevant satellite data without the need to build and launch their own. Thus, both cost and time are saved,” explains Ronak.

The ‘Satellite Playground ‘, with democratic access that TakeMe2Space is aspiring to build will be in the LEO space and serve satellites upto 30 kg payload. The revenue model will be ‘Pay per use’. The Space Policy 2021 provides facilities for easy building, launching & operation of satellite by private players.

Interestingly, none of the core team members comes from a space background. Ronak is software professional who started with the Microsoft in Hyderabad in 2008. In 2011, he cofounded, NowFloats Technologies which offers SaaS solutions to Small and Medium Enterprises (SMEs), enabling a digital presence for them. In December 2019, Reliance Strategic Business Ventures Limited (RSBVL), a wholly-owned subsidiary of Reliance Industries Limited (RIL) acquired it.

The radiation coating

The product is made from a special coating of tantalum (Ta), a dense metal that acts like a strong shield against harmful radiation in space. This coating can be applied to satellite parts, protecting them from the harsh environment and extending their lifespan.

The implications of this technology are vast. Cheaper, more durable satellites could open up space to a whole new generation of players, from small startups to universities etc.

The RSEM is a module to test the effectiveness of Tantalum (Ta) coating for radiation shielding in space. Satellite builders today are dependent on radiation-hardened electronic components which have 60-90 weeks lead time and also 10 times the cost of non- hardened components.

The coating developed by TakeMe2Space would help satellite builders to reduce cost of the electronics and faster development cycle. The coating is significantly cheaper than traditional radiation shielding methods, making it a boon for budget-conscious satellite builders. It can be applied quickly and easily, saving time and money, claims the company.

Satellite builders can coat the chassis and extend the mission lifetime of their satellites. The STEM students and universities who are building experimental space missions have tight budgets, hence a radiation shielding coating would be the most effective way to build a satellite and yet aim for a longer mission lifespan.

Based on the feedback received from the January one POEM platform of the PSLV C58, TakeMe2Space is further working towards developing various Tantalum tapes which can just be pasted on the satellite chassis for the protection. This would make it easier for satellite builders to just apply tape to the chassis and enable radiation protection.