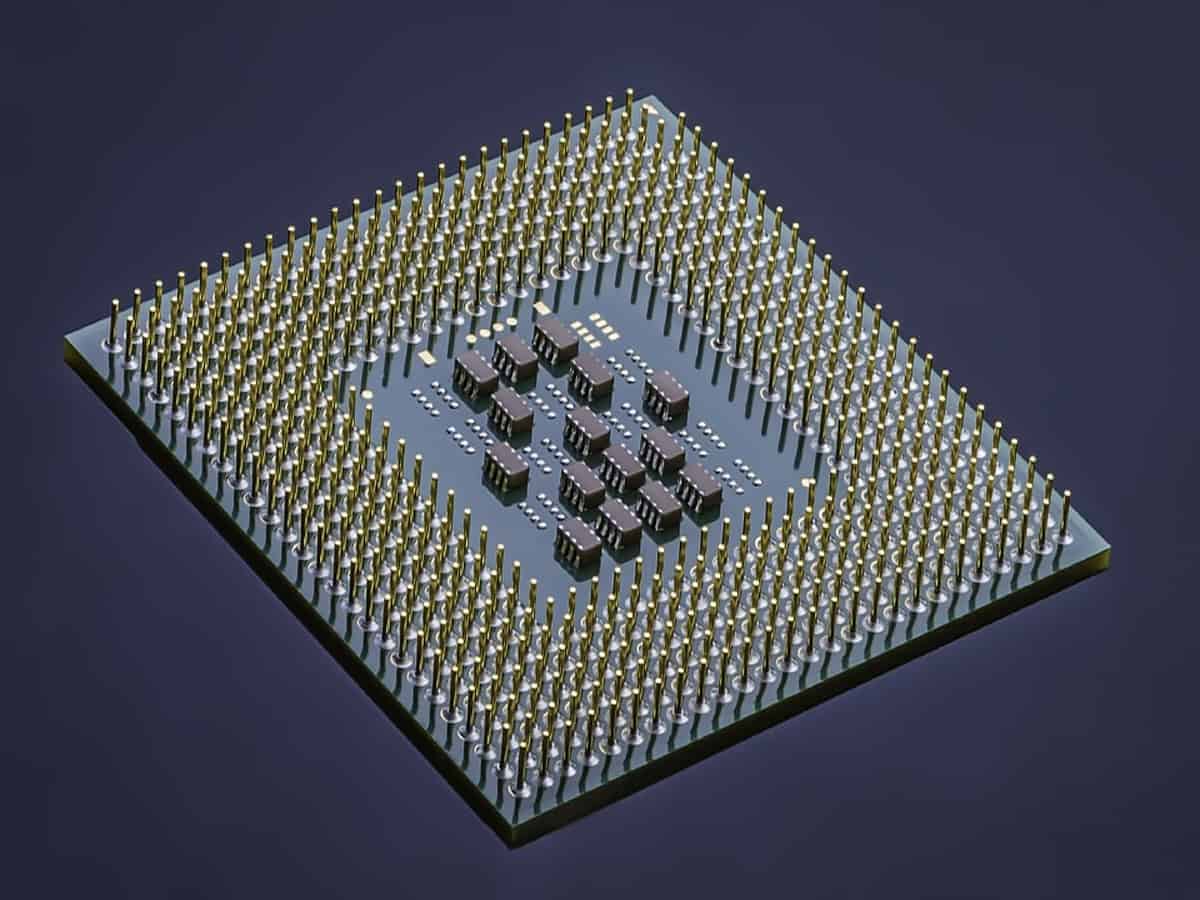

New Delhi: India has a $85 billion opportunity in the global $500 billion semiconductor manufacturing supply chain market comprising materials (gases, chemicals, minerals, equipment and services), a new report showed on Friday.

The Indian semiconductor industry can build materials, equipment and services capabilities, thereby making notable contributions to the global semiconductor manufacturing supply chain, according to the report by The India Electronics and Semiconductor Association (IESA).

The ongoing disruptions in the semiconductor industry and ESDM (electronic system design and manufacturing) supply chain have reiterated the importance of diversified and reliable resources.

Consequently, national governments and big corporations worldwide are adding futuristic manufacturing capabilities such as FABs and ATMPs to fuel the widespread national semiconductor independence trend by creating regional chip manufacturing hubs.

“The Indian semiconductor manufacturing supply chain ecosystem is at a nascent stage. With the unprecedented demand for semiconductors coupled with the rapidly changing landscape of the global semiconductor ecosystem, India has an opportunity to become a critical player in the semiconductor supply chain globally,” said Jitendra Chaddah, Country Manager, Global Supply Chain, Intel India.

To help enable the Indian ecosystem to cater to the global demands and create value for India, the IESA has formed a core interest Group (CIG).

The CIG has been formed with experts from the industry, government and academia who will lead the semiconductor manufacturing supply chain ecosystem development by augmenting policy support, skill development and forging global alliances.

“I call upon leaders from the ecosystem to join and participate in the CIG,” said Chaddah.

To sustain the current accelerated market demand for semiconductors and ultra-volatile markets, the growing number of semiconductor manufacturing facilities worldwide are constantly looking to diversify their supply chains.

“This new-age need opens tremendous opportunities for Indian industries to tap on and thrive,” said the report.

India, which aims to become a global semiconductor hub in coming years, is set to pump $30 billion into its technology sector to achieve independence on chips so that it isn’t “held hostage” to global suppliers.

The Indian government recently announced an outlay of Rs 76,000 crore (around $10 billion), under its production linked incentive (PLI) scheme, separately for the development of a semiconductor and display manufacturing electronics ecosystem.