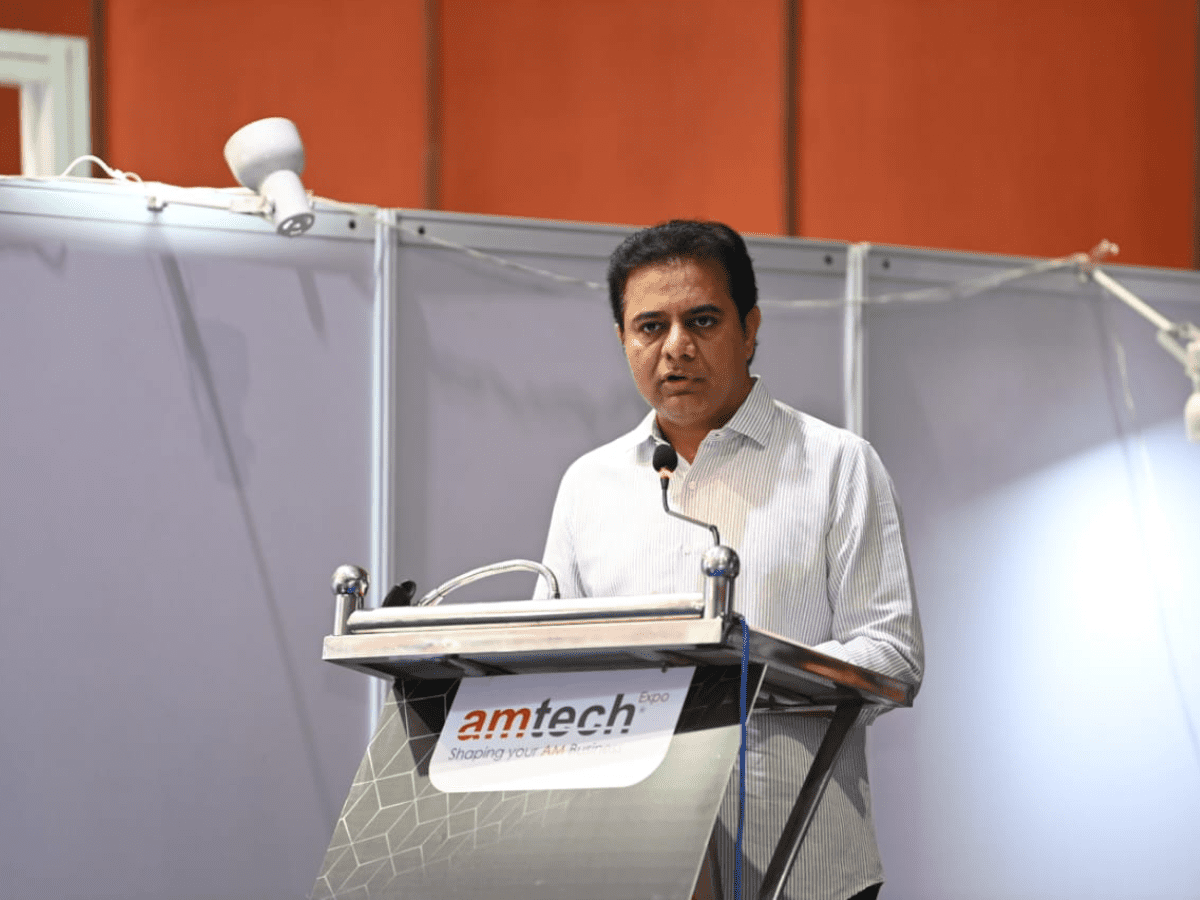

Hyderabad: IT and Industries minister KT Rama Rao on Friday stated that Telangana will ensure quick approvals for additive manufacturing (AM) solutions developed here and treat startups as partners rather than just as service providers.

Speaking at the opening of the Additive Manufacturing Technology (AMTECH) expo in Hyderabad, he stated that Telangana would quickly become a centre for additive manufacturing, which uses 3D printing to create tools and other useful components.

Additionally, he stated that Telangana would support technological advancements to ensure that they were built in India for the world.

He added that a 3D-printed engine had been utilised in the nation’s first private rocket, which was just launched by city-based Skyroot Aerospace.

In the fields of aerospace, defence, and medical equipment, 3D printing will be widely used. These three ecosystems are present in Hyderabad, which can be advantageous to the sector. In a few years, the industry is expected to grow to USD 65 billion.

On the campus of Osmania University, Telangana has already built the National Centre for Additive Manufacturing (NCAM), and throughout the course of the previous year, the centre has worked on numerous projects, Rao said.

Rao said Telangana has established system enablers such as the NCAM, T-Hub, TSIC, WeHub, RICH, TASK, and T-Works.

Telangana will seek to adopt 3D printing solutions in government agencies, with a focus on the engineering and construction sector. Up until now, some 1,500 startups have benefited. To encourage the use of modern technology in governance, the state also has an Emerging Technologies Wing.

Chief Executive Officer (CEO) of Centre for Military Airworthiness and Certification, APVS Reddy, a laboratory of the Indian Defence Research and Development Organisation, numerous modifications have been made to the certification procedures.

He added that it is willing to provide assistance to the businesses engaged in the additive manufacturing sector, stressing that the objective is to be proactive rather than reactive in the certification process. “The focus is on test adequacy and design adequacy as they relate to overall safety,” he said while emphasising the need for increased spending to upgrade the testing infrastructure for a quicker response.

He described additive manufacturing as a dawning industry.

“Telangana began working on 3D printing five years ago. The need is rising significantly, but MSMEs need to be made aware of it. The focus should be placed on innovation, affordability, and skilling. The materials’ accessibility should be taken into account because some must be imported and some can fall under the category of restricted resources. These will take longer to complete,” said Emerging Technologies Director L Rama Devi.